Hidrauliniai ir mechaniniai traukikliai

### Hydraulic and Mechanical Pullers

**Hydraulic Pullers:**

Hydraulic pullers are robust tools designed to remove gears, bearings, pulleys, and other press-fitted parts with ease and precision. They utilize hydraulic pressure to generate high pulling force, making them ideal for heavy-duty applications where manual force is insufficient.

– **High Force Capability:** Hydraulic pullers can exert significant pulling force, enabling the removal of stubborn or large components with minimal effort.

– **Precision Control:** The hydraulic mechanism allows for smooth, controlled pulling action, reducing the risk of damage to the parts being removed.

– **Universalumas:** Available in various sizes and configurations, hydraulic pullers can be used for a wide range of applications in automotive, industrial, and maintenance sectors.

– **Naudojimo paprastumas:** With ergonomic designs and often featuring detachable hydraulic cylinders, these pullers are user-friendly and can be operated by a single person.

– **Patvarumas:** Constructed from high-strength materials, hydraulic pullers are built to withstand the rigors of frequent use in demanding environments.

**Mechanical Pullers:**

Mechanical pullers are versatile tools that rely on manual force to extract gears, bearings, pulleys, and other components. They are a cost-effective solution for a variety of pulling tasks, offering reliable performance in less demanding applications.

– **Manual Operation:** Mechanical pullers are operated by turning a central screw, which drives the pulling jaws into position. This simple mechanism makes them easy to use and maintain.

– **Affordability:** Generally less expensive than hydraulic pullers, mechanical pullers provide an economical option for many repair and maintenance tasks.

– **Portability:** Lightweight and compact, mechanical pullers can be easily transported and used in various locations without the need for additional power sources.

– **Variety of Designs:** Available in two-jaw and three-jaw configurations, mechanical pullers can handle different shapes and sizes of components.

– **Adjustability:** Many mechanical pullers feature adjustable arms, allowing for a wide range of pulling distances and angles to suit different applications.

**Applications:**

Both hydraulic and mechanical pullers are essential tools in automotive repair, industrial maintenance, machinery assembly, and various other fields where the removal of press-fitted parts is required. Their ability to facilitate the safe and efficient extraction of components makes them indispensable in reducing downtime and improving productivity.

**Choosing the Right Puller:**

When selecting between hydraulic and mechanical pullers, consider the following factors:

– **Force Requirement:** For tasks requiring high pulling force, a hydraulic puller is the better choice.

– **Frequency of Use:** For frequent or professional use, the durability and ease of hydraulic pullers can be advantageous.

– **Budget:** Mechanical pullers are more affordable and may be sufficient for less demanding or infrequent tasks.

– **Portability:** If portability and ease of transportation are important, mechanical pullers offer a lightweight and convenient solution.

Investing in the right puller ensures efficient, safe, and effective component removal, enhancing the overall efficiency of maintenance and repair operations.

Showing 1–9 of 18 results

-

500-Ton Universal Hydraulic Puller Specifications

Skaityti daugiau -

10 Ton Split Type Hydraulic Grip Puller Set

Skaityti daugiau -

10-Ton, 2-Žandikaulis, Safety Cage Hydraulic Puller

Skaityti daugiau -

2 JAWS Heavy Duty Hydraulic Puller

Skaityti daugiau -

3 Jaws,100 Ton Safety Cage Hydraulic Puller

Skaityti daugiau -

50 Ton Three Jaws Heavy Duty Hydraulic Puller

Skaityti daugiau -

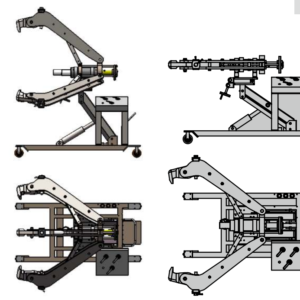

Auto Center Hydraulic And Mechanical Puller kit Range

Skaityti daugiau -

Bearing Cup Pullers

Skaityti daugiau -

Bearing Pullers

Skaityti daugiau