Bolting Tools

Uwendungen

Bau: Structural bolting, heavy machinery assembly, and maintenance.

Automotive: Engine assembly, wheel installation, and repair work.

Manufacturing: Assembly lines, machinery maintenance, and quality control.

Oil and Gas: Pipeline construction, flange assembly, and maintenance.

Aerospace: Aircraft assembly, maintenance, and repair.

Power Generation: Turbine assembly, maintenance, and high-pressure applications.

Advantages

Precision: Ensure accurate torque application, preventing over-tightening or under-tightening.

Safety: Proper bolting reduces the risk of joint failure and enhances structural integrity.

Efficiency: Specialized tools speed up the bolting process and reduce manual effort.

Durability: High-quality bolting tools are designed to withstand demanding industrial environments.

Bolting tools are essential for ensuring the integrity and reliability of bolted connections in a wide range of applications, providing the necessary precision, efficiency, and safety.

Showing 1–9 of 13 results

-

Liest méi

Liest méi

-

700 Bar Nut Splitters

Liest méi -

BNC-Series Nut Splitters

Liest méi -

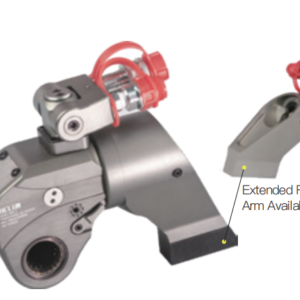

BSW Series Square Drive Hydraulic Torque Wrenches

Liest méi -

Hydraulic Nut Splitters Bolt Range: M45 – M90

Liest méi -

LONGLOOD BHNM Series Hydraulic Nuts

Liest méi -

LONGLOOD Hydraulic Bolt Tensioners Multi-Stage

Liest méi -

Low-Profile Hydraulic Torque Wrench 2349 Nm

Liest méi -

M12-M18, Integral Hydraulic Nut Splitters

Liest méi