haydroliko at mekanikal pullers

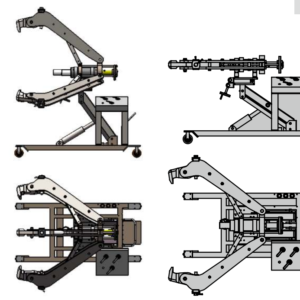

### Hydraulic and Mechanical Pullers

**Hydraulic Pullers:**

Hydraulic pullers are robust tools designed to remove gears, bearings, pulleys, and other press-fitted parts with ease and precision. They utilize hydraulic pressure to generate high pulling force, making them ideal for heavy-duty applications where manual force is insufficient.

– **High Force Capability:** Hydraulic pullers can exert significant pulling force, enabling the removal of stubborn or large components with minimal effort.

– **Precision Control:** The hydraulic mechanism allows for smooth, controlled pulling action, reducing the risk of damage to the parts being removed.

– **Versatility:** Available in various sizes and configurations, hydraulic pullers can be used for a wide range of applications in automotive, industrial, and maintenance sectors.

– **Ease of Use:** With ergonomic designs and often featuring detachable hydraulic cylinders, these pullers are user-friendly and can be operated by a single person.

– **Durability:** Constructed from high-strength materials, hydraulic pullers are built to withstand the rigors of frequent use in demanding environments.

**Mechanical Pullers:**

Mechanical pullers are versatile tools that rely on manual force to extract gears, bearings, pulleys, and other components. They are a cost-effective solution for a variety of pulling tasks, offering reliable performance in less demanding applications.

– **Manual Operation:** Mechanical pullers are operated by turning a central screw, which drives the pulling jaws into position. This simple mechanism makes them easy to use and maintain.

– **Affordability:** Generally less expensive than hydraulic pullers, mechanical pullers provide an economical option for many repair and maintenance tasks.

– **Portability:** Lightweight and compact, mechanical pullers can be easily transported and used in various locations without the need for additional power sources.

– **Variety of Designs:** Available in two-jaw and three-jaw configurations, mechanical pullers can handle different shapes and sizes of components.

– **Adjustability:** Many mechanical pullers feature adjustable arms, allowing for a wide range of pulling distances and angles to suit different applications.

**Mga Aplikasyon:**

Both hydraulic and mechanical pullers are essential tools in automotive repair, industrial maintenance, machinery assembly, and various other fields where the removal of press-fitted parts is required. Their ability to facilitate the safe and efficient extraction of components makes them indispensable in reducing downtime and improving productivity.

**Choosing the Right Puller:**

When selecting between hydraulic and mechanical pullers, consider the following factors:

– **Force Requirement:** For tasks requiring high pulling force, a hydraulic puller is the better choice.

– **Frequency of Use:** For frequent or professional use, the durability and ease of hydraulic pullers can be advantageous.

– **Budget:** Mechanical pullers are more affordable and may be sufficient for less demanding or infrequent tasks.

– **Portability:** If portability and ease of transportation are important, mechanical pullers offer a lightweight and convenient solution.

Investing in the right puller ensures efficient, ligtas na ligtas, and effective component removal, enhancing the overall efficiency of maintenance and repair operations.

Showing 1–9 of 18 results

-

500-Ton Universal Hydraulic Puller Specifications

Magbasa nang higit pa -

10 Ton Split Type Hydraulic Grip Puller Set

Magbasa nang higit pa -

10-Ton, 2-Jaw, Safety Cage Hydraulic Puller

Magbasa nang higit pa -

2 JAWS Heavy Duty Hydraulic Puller

Magbasa nang higit pa -

3 Jaws,100 Ton Safety Cage Hydraulic Puller

Magbasa nang higit pa -

50 Ton Three Jaws Heavy Duty Hydraulic Puller

Magbasa nang higit pa -

Auto Center Hydraulic And Mechanical Puller kit Range

Magbasa nang higit pa -

Bearing Cup Pullers

Magbasa nang higit pa -

Bearing Pullers

Magbasa nang higit pa